Table of contents

Create a culture that means business™

Schedule a demo with an Achievers solution expert today.

In manufacturing, keeping skilled workers isn’t just tough — it’s an art form. That’s why employee incentive programs for manufacturing have become so important: they help companies hold onto talent after the long process of hiring and training. But the reality is stark. In fact, only 32% of manufacturing employees see a long-term future at their company, according to the Achievers Workforce Institute (AWI). That’s a lot of investment heading straight for your competitors.

The right incentive programs change that story. Done well, they go beyond pay bumps to create a culture people want to stay in. And when recognition is built into the program, the impact multiplies — boosting engagement, strengthening safety, and keeping your workforce proud to put their name on the work they do.

How to incentivize factory workers

Motivating factory workers isn’t just about keeping the line moving — it’s about keeping people engaged, safe, and proud of what they do. That starts with regular, meaningful recognition for a job well done. It sounds simple, but the impact is big: AWI tells us that manufacturing employees who feel meaningfully recognized at least monthly are half as likely to look for work elsewhere.

Here are a few proven ways to keep your workforce motivated:

- Recognize often and meaningfully: Celebrate wins big and small, from hitting production targets to lending a hand on the line.

- Offer financial rewards: Use performance bonuses, profit-sharing, or spot awards during events like Manufacturing Day to give workers a tangible stake in the company’s success.

- Invest in career growth: Provide training, certifications, and skills development to show employees you’re building their future, not just their output.

- Add flexibility where possible: Offer extra time off, allow shift swaps, or adjust start times to support work-life balance without compromising production.

Put these together, and you’ve got more than an incentive program — you’ve got a workforce that’s motivated to stick around, stay safe, and deliver their best work every shift.

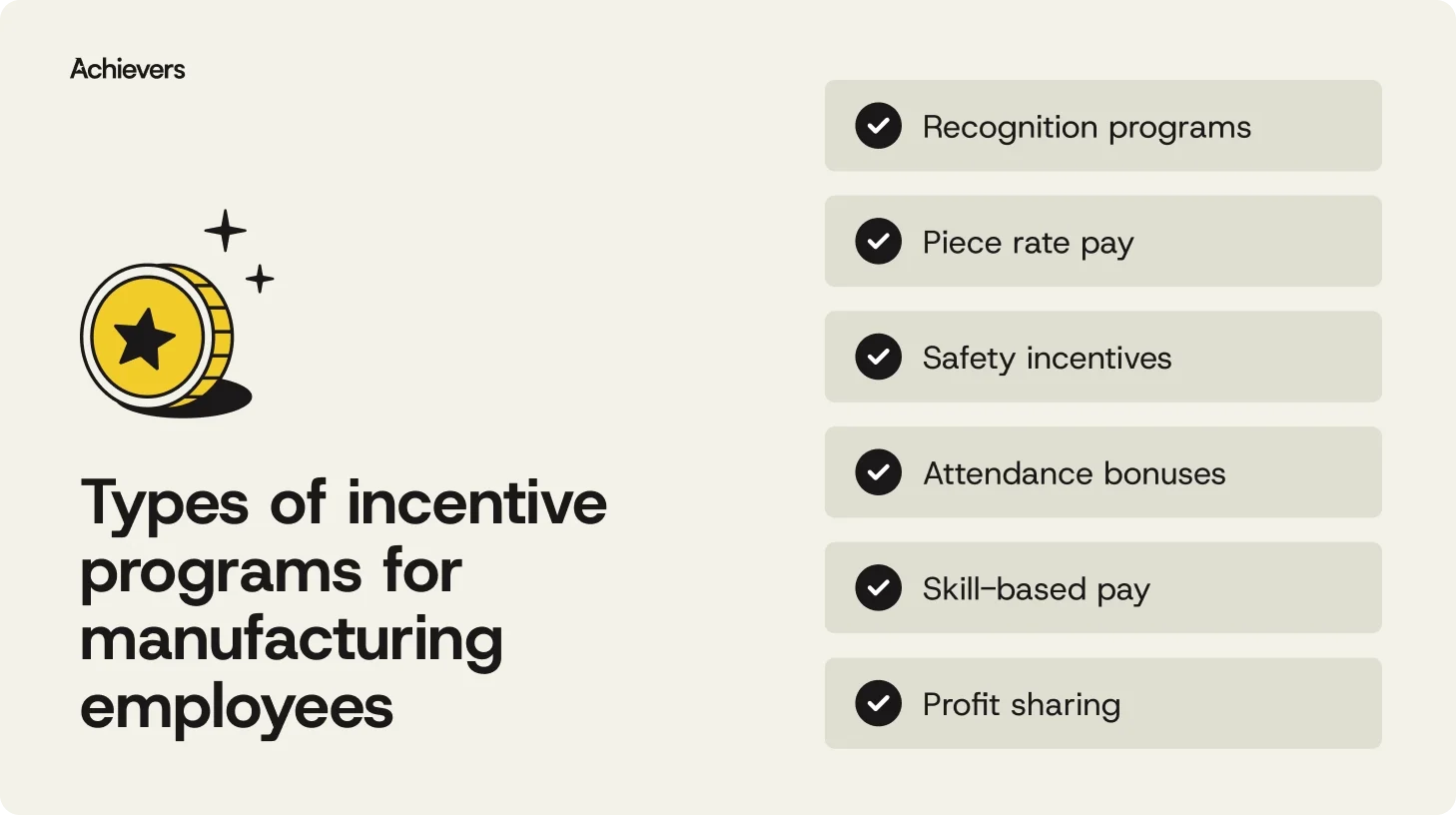

Types of incentive programs for manufacturing employees

Not every incentive works the same way — or for the same reason. On the factory floor, the best programs are the ones that speak to what actually drives people: being recognized, rewarded, and trusted to do their best work.

Here are some of the most effective options, and why they matter in a manufacturing setting:

Recognition programs

A recognition program is a formal way to consistently acknowledge employees for specific achievements, positive behaviors, and contributions. In manufacturing, that means calling out wins like hitting quality targets, preventing downtime, or stepping in to help a teammate. Publicly recognizing these moments is the type of reinforcement that shapes behavior. Do it often enough, and productivity becomes the default, not the exception.

Piece rate pay

Piece rate pay compensates workers based on the number of units they produce instead of a fixed hourly wage. It can turn “steady pace” into “how many can I finish before lunch?” by linking earnings directly to output. In a manufacturing setting, this can boost production rates and trim labor costs. Just make sure quality controls are in place — because no one wants a batch of defective parts just to hit a quota.

Safety incentives

Safety incentives reward employees for following protocols, reporting hazards, and contributing to a safe workplace. In manufacturing, it’s the everyday behaviors — wearing PPE, flagging a loose guard, shutting down faulty equipment — that keep people in one piece. Recognizing those habits lowers accidents and costs, sure, but it also sends a clear message: their well-being matters as much as the output.

Attendance bonuses

Attendance bonuses reward employees for maintaining consistent, reliable attendance over a set period. In manufacturing, an empty workstation can throw off an entire shift, so this incentive keeps schedules intact and production flowing. It’s also a subtle way to say, “We notice when you’re here, and it makes a difference.”

Skill-based pay

Skill-based pay increases compensation when employees acquire and master valuable, job-related skills. In manufacturing, that could mean learning to operate complex machinery, handling specialized materials, or mastering advanced safety procedures. For companies, it builds flexibility and resilience into the workforce. For employees, it’s a clear signal that expertise is recognized — and worth more than a pat on the back.

Profit sharing

Profit sharing gives employees a percentage of the company’s profits, typically distributed quarterly or annually. In manufacturing, it connects the dots between an efficient shift and a healthier bottom line. When the business does well and employees directly benefit, it turns “their profits” into “our profits” — boosting teamwork, commitment, and pride in the work.

Recognition: the key to effective employee incentive programs in manufacturing

In manufacturing, recognition it’s the fuel that keeps teams fired up, focused, and in it for the long haul. Incentive programs can hand out bonuses or perks, but recognition is the one that sticks. It turns safety into second nature, loyalty into a given, and solid performance into the everyday norm.

Here’s what you can expect:

1. Heightened engagement

On the factory floor, engagement can be the difference between work that’s good enough and work that hits every target. But connecting with every employee in a large, often shift-based workforce isn’t easy. Recognition closes that gap, giving employees a reason to stay engaged and connected to the bigger picture.

According to the AWI, 91% of employees would put in more effort if they felt valued. In manufacturing, that extra effort can mean hitting output goals, keeping quality high, and avoiding costly mistakes — all without adding more hours to the clock.

2. Strengthened retention with Gen Z and millennials

With a large portion of the manufacturing workforce heading toward retirement, younger talent is essential. The catch? Gen Z and millennials expect to feel valued and see a future with the company.

Recognition is exactly what you need to bridge the generational gap. AWI also tells us that employees recognized monthly are 4x more likely to see a long-term career at their company — and weekly recognition pushes that to 6x. That’s a major win in an industry where retaining trained talent is worth its weight in gold (or in this case, lower turnover costs and more consistent production).

3. An increase in skilled workers

Attracting skilled workers in manufacturing can feel like trying to find a needle in a haystack of parts. STEM talent is in short supply, and younger candidates may still see the industry as outdated or unsafe. Recognition helps shift that narrative.

When employees consistently feel appreciated, they’re not only more engaged — they’re also more motivated to develop and use their skills. According to Great Place to Work, recognized employees are 2.6x more likely to believe promotions are fair, 2.2x more likely to bring forward new ideas, and twice as likely to say their colleagues go above and beyond. That’s exactly the kind of culture that keeps skilled workers around — and draws new ones in.

4. Established sense of belonging

Recognition is the fastest way to remind people they’re not just a cog in the machine. It’s a signal that their work matters, their contributions are seen, and they’re part of something bigger.

High belonging is linked to a 56% increase in job performance. In manufacturing, that kind of lift can mean fewer errors, smoother collaboration across shifts, and a stronger safety culture. And in an industry where teamwork is essential, belonging isn’t just a perk — it’s a productivity driver.

5. Improved workplace safety

Safety is non-negotiable in manufacturing — but the way you reinforce it matters. Recognition programs that call out safe behaviors, from proper PPE use to hazard reporting, turn safety from a compliance checkbox into a shared priority.

When employees feel valued for their contributions to a safer workplace, they’re more likely to keep those behaviors up. Over time, that means fewer accidents, less downtime, and a workforce that’s engaged not just with production goals, but with protecting one another.

How to recognize employees in manufacturing

Recognition isn’t just about feeling appreciated; it’s about reinforcing the actions that drive results. Here are some practical, proven ways to put recognition into action on the factory floor:

Bonuses

Tie incentives to performance metrics or company profits to motivate employees to exceed expectations and contribute directly to business success.

Salary increases

Use merit-based or scheduled raises to reward experience and results, helping retain skilled talent and reflecting the true value of their contributions.

Profit-sharing programs

Share company profits to align employee interests with financial performance and create a stronger sense of ownership.

Additional vacation days

Offer extra paid time off to support work-life balance, reduce burnout, and keep morale high.

Flexible working hours

Where possible, allow shift swaps or flexible start times to boost productivity, improve job satisfaction, and signal trust.

Professional development opportunities

Invest in training and upskilling to demonstrate a long-term commitment to employees’ growth and provide skills that benefit both them and the company.

Awards and public acknowledgment

Celebrate achievements with awards or public recognition to reinforce the right behaviors, boost morale, and keep engagement high. When General Motors replaced their 23 local service awards programs with the new global Service Milestones Program, they were able to create a more consistent way to recognize and celebrate their employees’ careers at the company.

Want more ideas backed by data? Our manufacturing recognition playbook breaks down how top manufacturers are reducing turnover, boosting engagement, and driving safety through recognition — complete with real-world examples and proven strategies you can apply on the factory floor.

Recognition: the heart of employee incentive programs

The best incentive programs don’t just hand out rewards — they set the pace for the whole operation. Recognition is the difference between work that gets done and work people are proud to put their name on. It builds engaged teams, reinforces safe habits, and is the secret to improving culture in the manufacturing industry — keeping your best people even when other offers come calling.

That’s where Achievers comes in. Our platform makes recognition part of the daily routine, so calling out great work is as natural as clocking in. Whether it’s hitting a production goal, spotting a safety hazard, or helping a teammate keep the line moving, we make sure those moments don’t go unnoticed.